High Integrity Pressure Protection Systems

In the early 1990s, the UK Government established the Difficult Fields Working Group with invited representatives from oil & gas companies. One of the challenges identified was the development of offshore HP/HT fields. At the time, a number of discoveries had been made in the North Sea, but none of the fields had been developed due to both technical and cost challenges. One issue was whether it would be possible to introduce a pressure specification break on a subsea pipeline, thus enabling a lower pressure rating and reduction in costs. However, the key technical challenge was how to protect the de-rated pipeline from accidental overpressure.

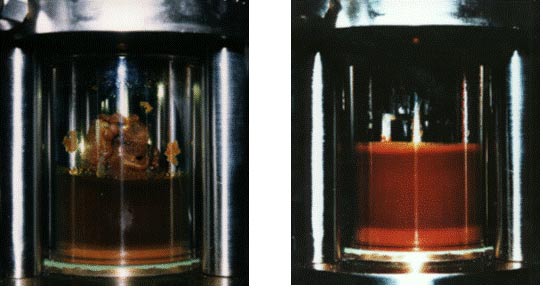

High Integrity Pressure Protection System

(Image © OneSubsea)

A project was launched in 1992 to review options for overpressure protection and to produce an outline design. The project was completed in 1995 and the result was the configuration that we see today, with dual fast-acting slam-shut isolation valves and a stand-alone control system with pressure sensors using 2 out of 3 voting. Following the publication of the results of this work, further development was undertaken by the equipment suppliers in order to qualify the components required. The first system was installed by Shell on the Kingfisher field in 1997.

More recent systems, installed since 2005, have also included a reinforced pipeline section downstream of the isolation valves, referred to as the fortified zone. This is to protect the pipeline whilst the valves close and also to protect against transient surge. A Recommended Practice was published in 2009.