Subsea Electric Power Distribution

With the increasing interest in subsea processing and the requirement to place more rotating equipment on the seabed, an additional challenge is to supply the electrical power required to drive the prime movers. This requires marinised transformers, switchgear and variable speed drives. Development started in the late 1990s, with two competing projects, both focused on shallow water applications. ABB launched the Subsea Electric Power Distribution (SEPDIS) project, whilst GEC Alstom (now part of GE) launched the Subsea Power Electrical Equipment Demonstrator (SPEED) project. Both projects produced prototype equipment that underwent successful submergence testing, with the SPEED project completing its test programme in early 1997. However, the oil price crash in 1999 led to further development work being halted due to lack of industry funding.

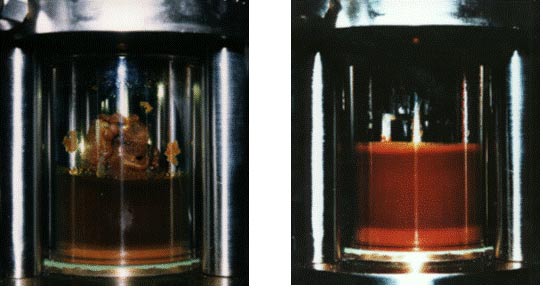

Subsea power transformer

(Image © ABB)

Development work restarted in 2005 with the Ormen Lange partners awarding a contract to GE for a power distribution system to supply subsea gas compression stations. The equipment has been undergoing submergence testing in Norway since 2012. However, Ormen Lange is a relatively shallow water application. In parallel, ABB, GE and Siemens have also been developing equipment suitable for 3,000 metre water depths and many of the components required are currently undergoing qualification testing. Whilst no orders have as yet been placed, the companies aim to complete their qualification programmes within the next two years, paving the way for the first systems to be installed by the end of the decade.

Even by industry standards, the technology has had a very long gestation period. However, this is due both the oil price crash of 1999 and also due to the unprecedented success of deep water exploration and development. However, as these fields deplete, the demand for subsea processing and associated subsea electric power technologies will increase in the future.